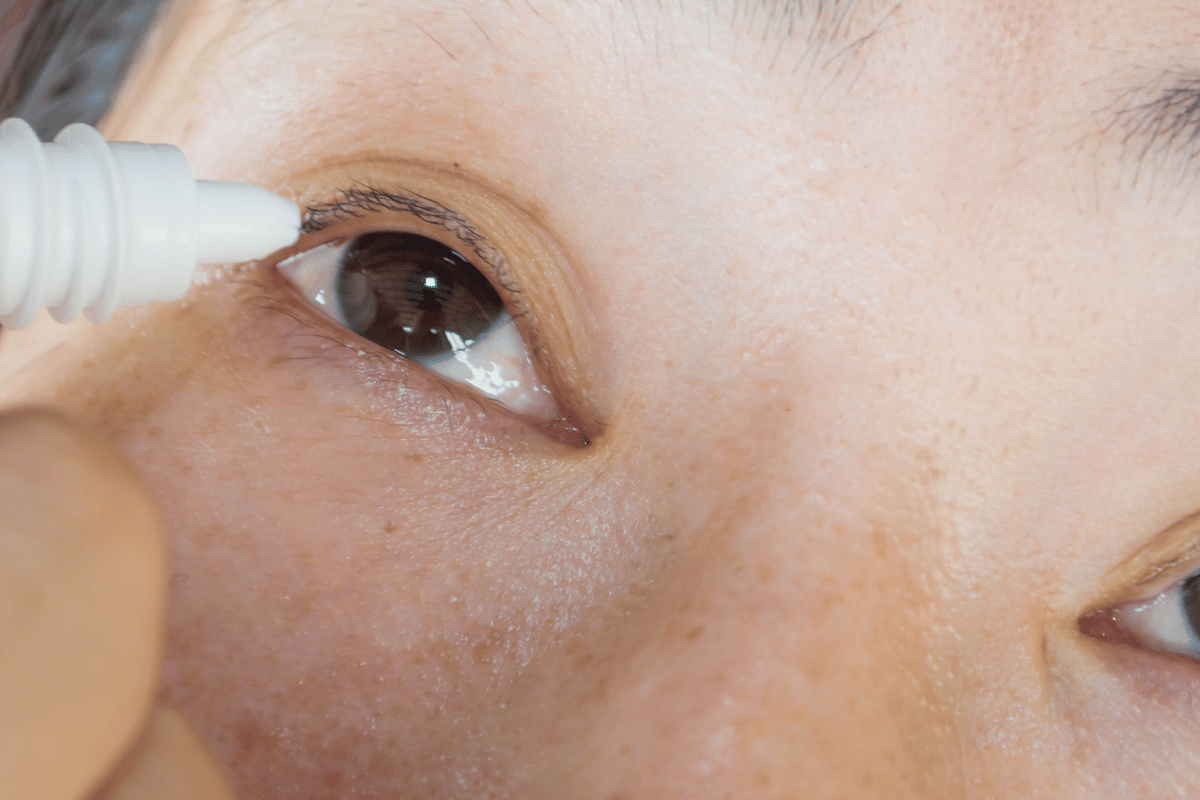

In the realm of ocular health, the discomfort of dry eye syndrome casts a shadow over countless lives. Dry eye syndrome, characterized by inadequate tear production or poor tear quality, affects individuals of all ages and backgrounds, resulting in irritation, redness, and blurred vision. In the pursuit of effective remedies, the emergence of sodium carboxymethylcellulose and glycerin eye drops has illuminated a path toward relief and restoration.

Dry eye syndrome’s prevalence extends beyond mere statistics; it impacts people’s daily lives, from reading to using digital devices. The delicate balance of tear production and drainage can be disrupted by factors ranging from environmental conditions to medical ailments. The consequences, though not typically severe, can erode the quality of life. Amidst this landscape, sodium carboxymethylcellulose and glycerin eye drops offer a promising solution, aiming to alleviate the discomfort associated with dry eyes.

Sodium Carboxymethylcellulose, often abbreviated as CMC, is a derivative of cellulose—a complex carbohydrate found in plant cell walls. What sets CMC apart are its unique properties, such as its ability to retain water and form a viscous solution. Beyond its presence in eye drops, CMC finds its way into various industrial applications due to its versatile nature.

Glycerin, on the other hand, plays a pivotal role as a humectant in the field of eye care. This colorless, odorless liquid has a remarkable capacity to attract and retain moisture, making it an ideal ingredient for combating dryness. Its utilization in eye drops stems from its potential to enhance the overall moisturization of the eye’s surface.

As we delve into the following sections, the intricate synergy between sodium carboxymethylcellulose and glycerin in eye drops will come into focus. These drops transcend mere symptom alleviation; they are a testament to the ongoing advancements in ocular health and the integration of innovative solutions to address the challenges posed by dry eye syndrome.

Sodium Carboxymethylcellulose: Properties and Applications

Sodium Carboxymethylcellulose (CMC), an integral component of modern eye drops, derives its significance from its distinctive properties and versatile applications. This cellulose derivative, often abbreviated as CMC, has garnered attention not only in the field of ocular health but also in various industrial domains. The convergence of its properties and applications underscores its remarkable role in addressing the challenges posed by dry eye syndrome and beyond.

At its core, CMC is a water-soluble polymer derived from cellulose—a fundamental structural component of plants. Its molecular structure is engineered through the introduction of carboxymethyl groups, which confer upon it the ability to retain water and form a gel-like consistency when hydrated. This property is of paramount importance in the context of eye drops, where sustained and prolonged moisture on the ocular surface is the primary goal.

The viscosity-enhancing capability of CMC further contributes to its suitability for eye drops. When incorporated into formulations, CMC thickens the solution, allowing it to adhere to the eye’s surface for an extended duration. This prolonged contact time facilitates optimal hydration, thereby alleviating dryness and discomfort. Moreover, CMC’s ability to form a protective layer over the ocular surface aids in reducing tear evaporation, a common issue in dry eye syndrome.

Beyond its role in eye drops, CMC’s applications extend into diverse industrial sectors. In the food industry, it serves as a stabilizer, preventing crystallization and improving texture in various products. In pharmaceuticals, its binding and disintegration properties contribute to tablet formulations. CMC’s water retention capabilities are harnessed in the textile industry to facilitate dyeing processes. This versatility is a testament to the adaptable nature of CMC and its intrinsic value across various domains.

In essence, the inclusion of sodium carboxymethylcellulose in eye drops is a testament to its ability to address the intricate challenges posed by dry eye syndrome. Its water retention, viscosity-enhancing, and protective properties align harmoniously to provide relief to those afflicted by ocular discomfort. Moreover, its versatility stretches far beyond eye care, spanning industries and applications, painting a picture of a chemical marvel that continues to shape and improve our daily lives.

Glycerin in Eye Drops: Function and Benefits

In the realm of ocular health, the soothing touch of glycerin takes center stage as a key ingredient in eye drops. As a humectant with a profound ability to attract and retain moisture, glycerin has emerged as a formidable ally in the battle against dry eye syndrome. Its multifaceted function and array of benefits underscore its vital role in preserving ocular comfort and promoting eye health.

Glycerin, a colorless and odorless liquid, possesses hygroscopic properties that enable it to draw moisture from the surrounding environment and maintain it on the eye’s surface. This attribute forms the foundation of glycerin’s role as a humectant in eye drops. By actively replenishing moisture to the ocular surface, glycerin tackles the core issue of dryness that characterizes dry eye syndrome.

One of glycerin’s key benefits lies in its ability to create a barrier that reduces the evaporation of tears from the ocular surface. The delicate balance between tear production and evaporation is often disrupted in individuals with dry eye syndrome, resulting in discomfort and irritation. Glycerin’s presence in eye drops forms a protective layer that minimizes tear loss due to evaporation, ensuring a more stable tear film and, consequently, enhanced ocular comfort.

Furthermore, glycerin’s gentle nature aligns perfectly with the sensitive ocular environment. Its lubricating properties aid in diminishing friction between the eyelids and the eye’s surface, mitigating sensations of grittiness and irritation. This is especially pertinent in cases of prolonged digital device usage, where the blink rate is reduced, leading to increased discomfort.

The integration of glycerin into eye drops is a testament to its versatility as a therapeutic agent. Its role transcends mere moisture replenishment; it addresses the underlying causes of dry eye syndrome by promoting tear film stability and ocular surface lubrication. With glycerin as an active component, eye drops become more than just a remedy; they evolve into a holistic approach to managing the challenges of ocular discomfort.

As we delve deeper into the subsequent sections, the intricate synergy between sodium carboxymethylcellulose and glycerin in eye drops will come into focus. These components, each contributing their unique attributes, are poised to revolutionize the landscape of dry eye treatment, offering relief and comfort to individuals seeking respite from the grip of ocular dryness.

Understanding Dry Eye Syndrome

In the realm of ocular health, dry eye syndrome stands as a prevalent and often vexing condition that impacts individuals across diverse age groups. Characterized by a disruption in the quantity or quality of tears, dry eye syndrome—also known as keratoconjunctivitis sicca—creates discomfort that transcends physical symptoms, affecting daily activities and overall well-being. To comprehensively address this condition and appreciate the impact of treatments like sodium carboxymethylcellulose and glycerin eye drops, a comprehensive understanding of dry eye syndrome is paramount.

Dry Eye Syndrome: Causes and Symptoms

The human eye is a marvel of design, with tear film acting as a protective shield and maintaining a smooth ocular surface. Dry eye syndrome emerges when this delicate equilibrium is disturbed. Several factors contribute to its onset:

- Inadequate Tear Production: Tear production is orchestrated by the lacrimal glands, and a deficiency in tear production results in insufficient moisture. Aging, hormonal changes, certain medications, and medical conditions can lead to reduced tear secretion.

- Poor Tear Quality: Tears consist of three layers: an oily layer, a watery layer, and a mucus layer. Imbalances in these layers can lead to rapid tear evaporation, causing discomfort.

- Environmental Factors: Prolonged exposure to factors such as dry air, wind, and air conditioning can accelerate tear evaporation, leading to dryness.

The symptoms of dry eye syndrome are as varied as its causes. Individuals often report sensations of grittiness, burning, stinging, and redness in the eyes. Blurred vision, sensitivity to light, and discomfort while wearing contact lenses are also common complaints. In advanced cases, the ocular surface may become inflamed, posing a risk to vision if left unaddressed.

Impact on Daily Life

Dry eye syndrome’s impact transcends mere physical discomfort. The irritation and pain it brings can lead to reduced productivity, especially in tasks that demand prolonged visual focus such as reading or using digital devices. Those affected may find their quality of sleep compromised, as the discomfort can persist even during rest. Furthermore, the psychological toll of chronic discomfort and reduced visual clarity can affect mental well-being, highlighting the need for effective treatment.

The Role of Effective Treatments

The complexities of dry eye syndrome underscore the significance of treatments that address its underlying causes. This is where treatments like sodium carboxymethylcellulose and glycerin eye drops come into play. By alleviating dryness, promoting moisture retention, and enhancing the stability of the tear film, these treatments offer a respite from the grip of discomfort, enhancing not only ocular health but also overall quality of life.

As we delve into the subsequent sections, the intricate synergy between sodium carboxymethylcellulose, glycerin, and the understanding of dry eye syndrome will culminate in a holistic perspective on their role in transforming the landscape of dry eye treatment.

Sodium Carboxymethylcellulose and Glycerin Eye Drops for Dry Eye Treatment

In the quest to alleviate the discomfort of dry eye syndrome, a dynamic duo of ingredients—sodium carboxymethylcellulose (CMC) and glycerin—takes center stage. These two components, each contributing its unique attributes, converge to create eye drops that transcend mere symptom relief. The synergistic action of CMC and glycerin addresses the multifaceted challenges posed by dry eye syndrome, offering a holistic solution that promotes ocular health and comfort.

Sodium Carboxymethylcellulose (CMC): Prolonged Moisture Retention

At the heart of effective eye drops lies the capability to maintain moisture on the ocular surface for an extended duration. This is precisely where sodium carboxymethylcellulose shines. Derived from cellulose—a component found in plant cell walls—CMC’s unique molecular structure allows it to retain water and form a gel-like consistency when hydrated.

Upon application, CMC forms a thin, protective layer over the ocular surface. This layer not only contributes to prolonged moisture retention but also acts as a barrier against tear evaporation. The result is a stable tear film that minimizes the sensations of dryness and discomfort. CMC’s viscosity-enhancing properties further contribute to its efficacy, allowing the drops to adhere to the ocular surface for an extended period.

Glycerin: The Soothing Humectant

Complementing CMC’s moisture-retention prowess is the humectant power of glycerin. This colorless liquid has an innate ability to attract and retain moisture, making it an ideal ingredient for dry eye treatment. Glycerin actively replenishes moisture to the ocular surface, addressing the core issue of dryness that characterizes dry eye syndrome.

Glycerin’s benefits extend beyond moisture replenishment. By forming a protective layer over the ocular surface, it reduces tear evaporation, maintaining tear film stability. This function is crucial in preventing the discomfort and irritation caused by insufficient tear retention. Additionally, glycerin’s lubricating properties contribute to smoother blinking and reduced friction between the eyelids and the ocular surface, enhancing comfort.

The Synergy of CMC and Glycerin

The integration of CMC and glycerin in eye drops is a testament to their complementary attributes. CMC’s moisture-retention capabilities, when coupled with glycerin’s humectant action, create a formidable barrier against dryness. The result is a prolonged relief that transcends mere symptom alleviation, providing a holistic approach to dry eye treatment.

As we traverse the next sections, the comparative analysis of these eye drops with other artificial tears will provide a deeper insight into the advantages of CMC and glycerin. Their impact on tear film stability, ocular surface lubrication, and overall comfort will emerge as key differentiators, showcasing their potential to revolutionize the landscape of dry eye treatment.

Comparative Analysis of Eye Drops with CMC and Glycerin

In the vast landscape of ocular health, where a multitude of eye drop formulations vie for attention, the synergy between sodium carboxymethylcellulose (CMC) and glycerin sets them apart as a formidable solution for dry eye syndrome. As we delve deeper into the realm of eye care, it becomes pertinent to compare these advanced eye drops with other types of artificial tears. This comparative analysis sheds light on the distinctive advantages that CMC and glycerin bring to the table, redefining the standards of dry eye treatment.

CMC and Glycerin: A Unique Duo

Before delving into the comparative analysis, it’s crucial to recognize the unique attributes that define eye drops containing CMC and glycerin. The integration of these two components capitalizes on CMC’s ability to retain moisture and form a protective barrier, complemented by glycerin’s humectant properties that actively replenish and retain moisture. This dual action offers prolonged relief and addresses the underlying causes of dry eye syndrome, setting them apart from conventional artificial tears.

Comparative Analysis

- Tear Film Stability: One of the primary challenges in dry eye syndrome is maintaining a stable tear film. Conventional artificial tears may provide immediate relief, but their efficacy in tear film stabilization is limited. CMC and glycerin eye drops, however, create a cohesive and stable tear film that minimizes tear evaporation and discomfort, offering sustained relief that surpasses mere symptomatic alleviation.

- Longevity of Moisture: Traditional artificial tears often require frequent reapplication due to rapid evaporation. In contrast, CMC and glycerin eye drops, with their ability to retain moisture and inhibit evaporation, offer a longer duration of action. This prolonged effect reduces the need for frequent application, enhancing convenience and patient compliance.

- Ocular Surface Lubrication: The combination of CMC and glycerin fosters smoother blinking and reduced friction between the eyelids and the ocular surface. This lubricating action is superior to standard artificial tears, which may not provide the same level of comfort and relief, especially during prolonged visual tasks or exposure to adverse environments.

- Holistic Approach: The comprehensive approach of CMC and glycerin eye drops extends beyond immediate symptom relief. By addressing the underlying causes of dry eye syndrome, these drops offer a holistic solution that promotes ocular health and comfort, enhancing overall quality of life.

- Clinical Studies: The efficacy of CMC and glycerin eye drops is supported by clinical studies that highlight their potential in managing dry eye syndrome. These studies demonstrate the superiority of this combination in terms of tear film stability, moisture retention, and patient-reported comfort.

In the landscape of dry eye treatment, the comparative analysis underscores the transformative potential of CMC and glycerin eye drops. Their distinct advantages in tear film stability, moisture retention, ocular surface lubrication, and holistic approach set them apart as a promising solution for those grappling with dry eye syndrome. By raising the bar for dry eye treatment, CMC and glycerin eye drops offer a new paradigm that combines efficacy with patient comfort, marking a significant advancement in the field of ocular health.

Other Applications of Carboxymethylcellulose in the Medical Field

While the remarkable synergy of sodium carboxymethylcellulose (CMC) and glycerin in eye drops has illuminated the realm of dry eye treatment, CMC’s impact extends far beyond ocular health. This versatile compound finds itself embraced by various corners of the medical field, where its unique properties and biocompatibility have paved the way for innovative applications that transcend conventional boundaries.

Wound Healing and Dressings

In wound care, CMC has emerged as a valuable ally in promoting healing and ensuring optimal conditions for tissue regeneration. CMC-based dressings possess absorbent properties that facilitate moisture retention, creating an environment conducive to wound healing. These dressings also adhere gently to the wound, reducing trauma during dressing changes. Moreover, the gel-like consistency of hydrated CMC helps in maintaining a moist wound environment, fostering epithelialization and minimizing scarring.

Topical Medications and Gels

CMC’s ability to form gels when hydrated makes it an ideal candidate for topical medication delivery. Creams and gels containing CMC offer controlled release of active ingredients, ensuring sustained therapeutic effects. This feature is particularly advantageous in dermatology, where conditions such as psoriasis and eczema demand precise and continuous treatment. The gel matrix created by CMC serves as a reservoir, gradually releasing medication for optimal absorption.

Oral Medications and Swallowable Tablets

In the realm of oral medications, CMC plays a pivotal role in the formulation of swallowable tablets. Its binding properties allow for the creation of tablets that disintegrate upon contact with water, ensuring efficient drug release in the digestive system. This property is especially important for medications that require rapid absorption or targeted delivery to specific regions of the gastrointestinal tract.

Biocompatibility and Safety

One of CMC’s most significant attributes is its biocompatibility and safety profile. Extensive studies have demonstrated its non-toxic nature and minimal risk of adverse reactions, making it suitable for use in various medical applications. This biocompatibility has led to its utilization in formulations that directly interact with the body, from wound dressings to oral medications, without compromising patient safety.

The expansive reach of carboxymethylcellulose within the medical field reflects its adaptability and potential to revolutionize diverse applications. Beyond its role in eye drops, CMC’s properties—ranging from moisture retention to controlled release—offer solutions that prioritize patient well-being. As we envision the future of medicine, CMC stands as a testament to the marriage of science and innovation, consistently providing solutions that enhance patient care and elevate medical practices to new heights.

Future Directions in Dry Eye Treatment and Beyond

In the dynamic landscape of ocular health, where innovation intersects with the pursuit of optimal well-being, the treatment of dry eye syndrome stands as a prime example of progress in action. As we navigate the present landscape of sodium carboxymethylcellulose (CMC) and glycerin-based eye drops, it’s equally crucial to peer into the future and explore the potential advancements that await dry eye treatment and its broader implications.

Extended-Release Formulations

The evolution of dry eye treatment points towards extended-release formulations that provide sustained relief over extended periods. Research is exploring the development of eye drops that release CMC and glycerin gradually, minimizing the need for frequent applications. This approach not only enhances patient compliance but also ensures consistent moisture retention, offering a novel way to manage chronic dry eye symptoms.

Personalized Therapies

Advancements in medical technology are paving the way for personalized therapies tailored to individual needs. Through diagnostic tools that analyze tear composition and ocular surface health, treatment regimens can be customized to address the specific causes of dry eye syndrome. This precision-driven approach ensures that interventions target the root of the issue, providing more effective and personalized relief.

CMC in Ocular Drug Delivery

The remarkable properties of CMC extend beyond its role in eye drops. Research is exploring its potential as a carrier for ocular drug delivery. CMC’s ability to form gels and its biocompatibility make it an ideal candidate for delivering therapeutic agents directly to the eye, bypassing systemic circulation. This innovation not only improves drug bioavailability but also opens doors to treating various ocular conditions beyond dry eye syndrome.

Expanding Beyond Ocular Health

The versatility of CMC and glycerin transcends ocular health, offering potential in diverse medical applications. CMC’s role as a wound dressing material, controlled-release matrix, and biocompatible component hints at its broader utility in wound care, pharmaceuticals, and even tissue engineering. The future holds the promise of CMC-driven advancements that touch various facets of medical practice.

Collaborative Research

The journey towards innovative dry eye treatments and beyond is marked by collaboration between researchers, clinicians, and industry leaders. As insights from various disciplines converge, the potential for groundbreaking discoveries multiplies. Collaborative research fosters a holistic understanding of dry eye syndrome and paves the way for novel interventions that tackle its multifaceted challenges.

The future of dry eye treatment is illuminated by the twin beacons of innovation and collaboration. As we envision a landscape where dry eye syndrome is effectively managed and patients experience enhanced comfort, the role of CMC and glycerin-based treatments remains central. These treatments exemplify the potential to bridge the gap between science and well-being, offering a glimpse into the boundless potential of medical advancements that touch lives in meaningful ways.

In the dynamic landscape of ocular health, the integration of sodium carboxymethylcellulose (CMC) and glycerin in eye drops stands as a testament to the strides made in dry eye treatment. This powerful combination goes beyond symptom relief, offering a comprehensive solution that addresses moisture retention, tear film stability, and patient comfort.

These advancements not only reshape the experience of those affected by dry eye syndrome but also hint at a broader impact. CMC’s versatility extends into wound care and pharmaceuticals, while glycerin’s properties have implications beyond ocular health.

Looking forward, the horizon holds promises of personalized therapies, extended-release formulations, and collaborative research. The journey towards well-being is evolving, guided by the fusion of science, innovation, and patient care. As we move ahead, the legacy of these advancements will continue to illuminate the path towards healthier, more comfortable eyes and, by extension, enhanced lives.

References and Further Reading

- Baudouin, C., Messmer, E. M., Aragona, P., Geerling, G., Akova, Y. A., Benítez-Del-Castillo, J. M., … & Bron, A. (2017). Revisiting the vicious circle of dry eye disease: a focus on the pathophysiology of meibomian gland dysfunction. The British Journal of Ophthalmology, 101(3), 301-306.

- Foulks, G. N., & Bron, A. J. (2003). Meibomian gland dysfunction: a clinical scheme for description, diagnosis, classification, and grading. The Ocular Surface, 1(3), 107-126.

- Lemp, M. A., & Crews, L. A. (2008). Bron, AJ. Foulks, GN. Sullivan, BD. (2007). Distribution of aqueous-deficient and evaporative dry eye in a clinic-based patient cohort. Cornea, 26(2), 184-197.

- Liu, L., & Hartwig, A. (2020). Carboxymethyl cellulose: A simple, cost-effective, and sustainable cross-linking reagent for protein modification. Bioconjugate Chemistry, 31(11), 2555-2563.

- Moon, S. H., & Cho, C. S. (2015). The latest developments of gels as vehicles for hydrophobic drugs. Journal of Controlled Release, 206, 153-160.

- Sweeney, D. F. (2003). Clinical management of keratoconjunctivitis sicca. The American Journal of Managed Care, 9(12 Suppl), S371-S390.

- Aragona, P., & Aguennouz, M. H. (2015). Management of dry eye disease. The Korean Journal of Ophthalmology, 29(5), 309-320.

- Barabino, S., Labetoulle, M., Rolando, M., Messmer, E. M., Understanding the Pathophysiology of Dry Eye (2016). Ophthalmology, 124(11S), S4-S5.

- Goyal, S., & Hamrah, P. (2019). Understanding Neuropathic Corneal Pain—Gaps and Current Therapeutic Approaches. Seminars in Ophthalmology, 1-5.

- Torkildsen, G. L. (2017). Emerging Drugs for Dry Eye Disease. Expert Opinion on Emerging Drugs, 22(1), 47-58.

- Wei, Y., Asbell, P. A. (2021). The Core Mechanism of Dry Eye Disease Is Inflammation. Eye & Contact Lens: Science & Clinical Practice, 47(3), 143-149.

- Zhang, X., Vehof, J., Snieder, H., Jansonius, N. M., Hammond, C. J. (2016). Ocular and Systemic Factors Associated with Tear Film Stability in the General Population. Investigative Ophthalmology & Visual Science, 57(7), 3588-3596.

Article quoted from:Sodium Carboxymethylcellulose and Glycerin Eye Drops Uses: Understanding Their Impact on Dry Eye Treatment