Packaging serves as the first line of defense against loss and degradation of the product during transportation and storage. But what ensures these packages are good enough to withstand the rigors of shipping and handling? The Box Compression Tester is a cutting-edge tool used for the compressive force endurance testing of packaging materials. This blog will provide an in-depth explanation of the essence of box compression testing, why industries that depend on packaged goods should consider this process, and how to achieve cost efficiency, sustainability, and customer satisfaction through the use of a suitable testing machine. Whether your field is manufacturing, logistics, or quality assurance, this article will provide you with pertinent information to enhance your packaging endeavors.Click here to read more

The Importance of Box Compression Testing

With the ability to withstand pressure and weight during storage and transit, packaging materials must be tested to ensure they can withstand the pressure and weight they encounter during these periods. This test determines the maximum load the box can carry before being deformed or failing, thereby ensuring that the products inside are safe from damage. It proves highly useful for shipping industries, as it helps minimize product loss, customer complaints, and overall dissatisfaction. Furthermore, box compression testing can be conducted by companies to assist in modifying packaging designs for a good balance of materials used with optimal strength.- sustainability and cost-efficiency.

Understanding Compression Strength

Various factors influence compression strength, including their box design, material cast, and environmental conditions. The type of flute, corrugated board thickness, and quality of adhesive determine how much weight the box can hold. External factors could set in and erode the box’s structural strength over time-an example of such would be situations dependent on the alternatives of humidity and temperature. Standard tests, such as Edge Crush Tests (ECTs) and Box Compression Tests (BCTs), are used to determine the compressive strength of the box, thereby assessing its suitability as a shipping standard. With this back-of-the-house expertise, firms can design packaging that better meets industry requirements and keeps the product safe during shipment.

Benefits of a Box Compression Tester

With this, a Box Compression Tester provides several essential functions for businesses that require reliable packaging solutions. First and foremost, it ensures that the structural integrity of the packaging is maintained by determining the highest possible compression strength of the box under bearing loads, without damage during handling and transit. Through such ultra-institutional testing, companies can determine the proper materials and box specifications based on the weight of their item or employ special packaging for especially heavy or fragile items to make the product safer.

The Box Compression Tester, in conjunction with the packaging design process, can efficiently introduce alternative methods for reducing unnecessary material costs without compromising necessary strength and reliability. Furthermore, it ensures compliance with industry standards and regulations, ensuring the packaging meets the accepted standards for transportation and handling. Routinely subjected to testing, the process of quality control can be improved to ensure that packaging performance is present and consistent across various operations involving strength tests.

Competition in any industry necessitates product protection; hence, with a Box Compression Tester, one can limit the theft of products, minimize product loss resulting from damage to goods, and increase customer satisfaction through enhanced delivery ability. This is how the tool boosts efficiency, sustainability, and worth.

Applications in Packaging Quality Control

A box compression tester is an essential tool for packaging quality control, ensuring the strength and durability of packages throughout the various stages of the supply chain. These devices ascertain whether the packaging will withstand pressures during stacking for storage or transit. These are particularly common in package industries that concern food and drinks, pharmaceuticals, and e-commerce, where the good packaging demonstration is paramount to product protection and carton compression.

By verifying through standardization that a box meets maximum compressive load requirements, manufacturers can ensure adequate material strength while controlling the amount of materials used in paper and packaging. This promotes saving by avoiding overly large packages. Box Compression Testers will also help the packaging industry comply with industry standards and customer-specific packaging requirements, resulting in consistent product delivery.

How Box Compression Testers Work

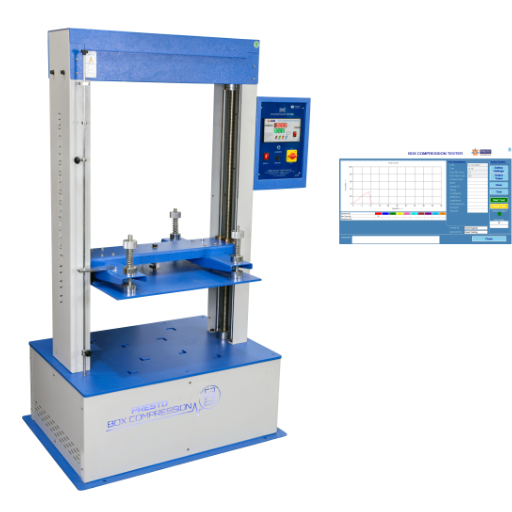

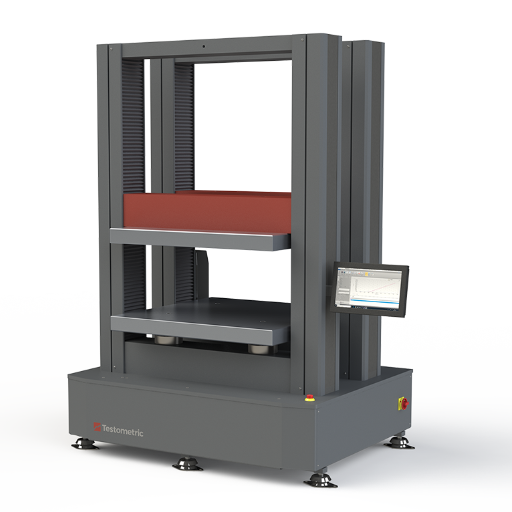

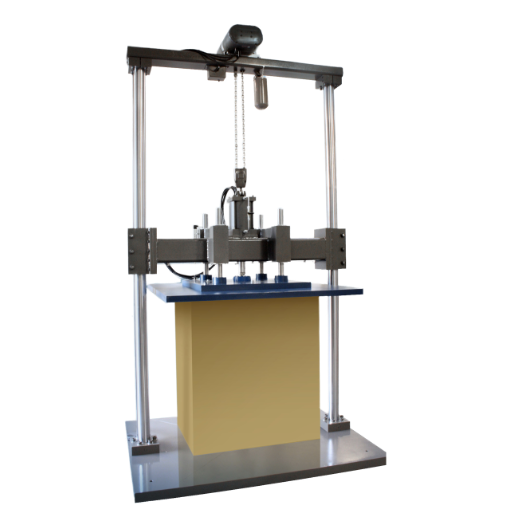

Box Compression Testers work by applying a controlled compressive force on a box until it deforms or fails. The box is secured on the machine’s platform, ensuring it is properly aligned. The machine then moves the platen downwards steadily, measuring the force applied and the resistance to that force exerted by the box. This figure is subsequently obtained to determine the maximum load a box can withstand before collapse. The utmost precision and reliability of test results are what make these testers crucial for evaluating the strength and durability of packaging.

Overview of the Testing Machine Mechanics

The box compression test machine utilizes numerous fine mechanical components and high-level sensors to analyze packaging strength. The mechanization is composed of a movable platen that applies a pre-set pressure uniformly to the box. This can be achieved through hydraulic or screw mechanisms, ensuring that every possible force is used uniformly. The load cells of this machine are highly advanced, which measure the force applied while a computer program simultaneously stores the data for later analysis. The parameters (such as distance) can all be set before the test to fit different dimensions of box samples and materials, allowing for calibration to many standards used by various industries. To increase repeatability and precision, these machines are crucial in quality control, enabling manufacturers to optimize packaging design for effective performance in real-world conditions.

Types of Compression Tests Performed

- Top-to-Bottom Compression Test

Here, a maximum force will be exerted on the box or container with pressure applied vertically. During this test, it will be determined whether the product can be stacked or not, and whether the packaging has the structural integrity to withstand transport and storage.

- Edge Crush Test (ECT)

This test was performed on corrugated material. It tests the edgewise strength of the material for predicting resistance to compression of the box, using a test method designed explicitly for this purpose. It is crucial in estimating how well the box will stack and how much load it can support.

- Flat Crush Test (FCT)

The purpose of the FCT is to check the compression strength of the flute structure of corrugated boards. It exposes the linerboards to direct and uniformly distributed pressure, measuring their resistance and maintenance of cushioning properties.

Measuring Box Compression Strength

As a vital parameter in packaging design, box compression strength refers to the maximum pressure or force that a box can withstand before it loses its shape, as determined by a strength test. To determine the strength of the box, it is tested according to commercial-standard test procedures, such as the Box Compression Test. In this test, a gradually increasing force is applied to the box until it collapses, providing precise insight into its stacking performance and load-bearing strength.

Some of the key factors affecting a BCT test result are the type of materials used, flute structure, box dimensions, and quality in its manufacture. Other variables that affect performance include humidity and temperature levels. By utilizing data generated from BCT, manufacturers can design and tailor materials to meet their durability requirements in a cost-effective manner. Accurate testing protects the content, prevents waste, and guarantees safe handling throughout the logistics chain.

Choosing the Right Compression Testing Equipment

The main factors to consider when choosing compression testing equipment include accuracy, reliability, and compatibility with the specific testing requirement at hand. Machines ideally suited to the size and type of materials tested should be chosen based on testing for the capacity of the actual load and precise measurement. Additionally, user-friendly controls and software would be helpful for collecting data and analyzing it. Give preference to devices manufactured by companies with an established history of quality and support so as to remain reliable and work well in the long run.

Factors to Consider When Selecting a Tester

Types of Testing Application

You have to decide what exactly you want to test: tensile, compression, or fatigue testing; therefore, there should be a machine that can truly perform these tests. Verify that it is compatible with the type of material or standards used in your industry to ensure reliable results.

Capacity and Grinding Precision

Select machines that match the load range of your application in terms of both strength and precision. Machines have to be highly accurate and repeatable if the testing criteria are more demanding in these industries.

Ease of Use and Software Integration

The testers should have an intuitive graphical user interface, facilities, and good software integration. It will enhance the efficacy and accuracy of testing by facilitating automated data collection, reporting, and real-time monitoring.

Durability and Manufacturer Reputation

An investment should be made in instruments from manufacturers who have a reputation for quality construction and good customer support. More durable equipment will save you money in the long run, as it requires less maintenance and is less prone to breakdowns.

Budget and Scalability

Assessment of the allotted budget would ensure that the product offers scalability for any future test requirements. Cost-effectiveness over advanced functionality must keep the investment very much sustainable.

Considering these aspects would aid in choosing a test equipment that fulfills present needs while allowing for future goals.

Comparing Box Compression Tester Prices

Several factors must be considered when comparing box compression tester prices to ensure the best value for the purchase. Such testers can even set one back anywhere in the range of a few hundred to a few thousand dollars, depending on the brand, features, or capabilities.

- Basic Models

Entry-level box compression testers typically cost between $300 and $1,000. These models provide standard functionalities for smaller-scale operations or basic testing needs. Thus, any company with a tight budget and minimum test requirements will benefit from this model.

- Mid-Range Models

The mid-range models typically cost between $1,000 and $5,000 and feature a digital display panel, automatic functionality, and the highest accuracy. These would be for medium-scale companies, intermediate in cost and performance measure.

- VIP Models

Depending on whether they are advanced or industrial-grade models, one can assert that these models can be priced beyond $5,000, with lucrative features including configurable testing parameters, precision, and solid software integration. They are best suited for settings with extensive and specialized applications, yielding the highest level of performance.

To make an informed decision, consider several quotes from top providers and manufacturers while evaluating whether the model meets your specific testing requirements. Also, consider your maintenance costs, as well as warranties and potential upgrades, when determining the acquisition price.

Top Brands and Models of Compression Strength Testers

Measuring compression strength belongs to a domain dominated by top brands and models, such as Instron, MTS, and Tinius Olsen; therefore, these well-established names should be considered. Considered among the best, these brands produce highly specialized equipment that offers features such as precise load application and measurement, and the configurations can be adjusted according to specific tests. The Instron 6800 Series is highly regarded for its accuracy and features an easy-to-operate interface, while the Super L series by Tinius Olsen is known for its rugged build and dependable performance. If you explore the offerings of these great industry names, you will undoubtedly find a machine fulfilling your particular objectives in testing.

Compliance with Industry Standards

Ensuring that individuals comply with industry standards is a way to maintain the accuracy and reliability of a specific piece of testing equipment. Models such as the Instron 6800 Series and the Super L series of Tinius Olsen are three reputable examples that have been designed to meet or exceed international standards, including those established by ASTM and ISO. These standards go a long way in assuring dependable performance and results across testing applications. Selecting equipment that meets these standards ensures your processes align with regulatory requirements and industry best practices.

Relevant Standards for Packaging Testing

Packaging testing must be performed adhering to the utmost standards for reliability, safety, and performance, among others. Some key standards include:

- ASTM D4169 – It involves performance testing for shipping containers and systems. The testing considers the effects of a distribution environment, including vibration, compression, and impact, so that a package can withstand real-life conditions.

- ISO 11607 – This standard pertains to the packaging of terminally sterilized medical devices. It covers materials for packaging, preformed sterile barrier systems, and packing processes, all of which ensure that sterility is maintained until the point of use.

- ISTA Testing Series – Developed by the International Safe Transit Association, the ISTA 1, 2, and 3 series provide testing protocols that instruct on pre-shipment testing, minimizing product damage while enhancing packaging for transport.

This ensured compliance with regulatory and industrial requirements. It also enhanced product integrity and customer satisfaction. Such alignment ensures that the testing processes can meet these standards set by the relevant testing instrument.

How Testing Ensures Regulatory Compliance

Testing performs pivotal roles that put a product to the test against regulatory standards. They check safety, reliability, and performance standards for the product. Regulatory bodies draft regulations to protect consumers, regulate industry practices, and maintain environmental sustainability. In this way, testing helps businesses demonstrate conformity with these standards, thereby averting risks such as a levy, product recall, or outright defamation.

Some key issues addressed include chemical safety, electrical compliance, and packaging suitability, making them industry-specific standards, such as those established by the FDA, ISO, and ASTM, among others. Companies thus establish a relationship of trust with their customers and stakeholders while also ensuring they are legally free and clear. In-depth testing presents the possibility of detecting non-compliance early on, thereby correcting any discrepancies and saving resources and time.

Impact of Standards on Packaging Safety

Segmentation of packaging safety involves standards that must be clearly defined, outlining the functional and consumer protection aspects with which compliance will be assessed. In one instance, the FDA implemented all food packaging regulations to prevent contamination to the maximum extent possible, while also preserving product integrity through the strength testing of packaging materials. ISO standards, on the other hand, relate to potential changes in quality management systems and environmental aspects, thereby providing packaging solutions that are environmentally sustainable and efficient. ASTM is concerned with testing materials to confirm whether they can withstand, resist, and be safe under various conditions, especially for packaging materials with high strength.

When these standards are met, the risks of contamination, leakage, and breakage are mitigated, and international trade can be facilitated through compatibility among the markets of various countries. The frameworks also encourage innovations because manufacturers may, through packaging solutions, provide a means of enhancing safety standards and user experience while considering sustainability. These standards, once established, protect public health, and the liability of the business decreases while upholding quality and responsibility in the paper and packaging industry.

Frequently Asked Questions (FAQs)

What is a box compression tester machine?

A box compression tester machine primarily tests the weight applied to packaging materials, especially to corrugated boxes, to induce deformation. It is a crucial factor in ensuring that packaging is strong enough to provide protection during shipping and handling, especially for corrugated cartons.

How is a box compression tester used?

The box compression strength tester applies an intermediate load on a box until it is deformed or crushed. Manufacturers and suppliers are hence provided with test information that describes the strength of their packaging materials. Testing against international standards is widely accepted, as it ensures results with consistency and accuracy.

What are the benefits of using a compression tester in packaging testing?

The compressed tester gives valuable insight into the stackability and compressive ability of the cartons. By testing the strength of packaging materials, companies can enhance their packaging, thereby reducing product damage during shipping and ultimately meeting their industry standards.

What materials can we test using the box compression tester?

The box compression tester is used to test a wide range of materials, including corrugated boxes, paper boxes, honeycomb boxes, beehive crates, and paper cases. It is essentially vital for manufacturers to determine how resistant their packaging is to compression.

What are the distinctions between a stacking test and a compression test?

With a stacking test, the packaging is subjected to pressure due to the weight of other boxes stacked on top of it, whereas with a compression test, the maximum load a box can bear without deformation is the issue. These tests are primarily conducted to verify whether the packaging will withstand the stresses of storage and transport.

How can I ensure that my box compression tester is accurate?

Generally, the tester for corrugated cartons must be calibrated regularly to ensure its accuracy. Proper maintenance procedures should always be carried out. Through standards of international applicability, the reliability of test results will be upheld, facilitating a precise evaluation of box strength.

What are the implications of test data acquired from a box compression strength tester?

The test data from a box compression tester provides insight into how cartons perform under specific conditions. With such data, manufacturers and suppliers are better equipped to select materials and package designs, thereby ensuring improvements in the quality and strength of their products.

Is a box compression strength tester fit for lab testing?

Indeed, box compression strength testers are used in lab testing to determine the compression strength and performance of packaging materials. The tester enables testing under specified conditions and the collection of measurements. The tester is an irreplaceable piece of equipment in quality assurance and product development activities.

What considerations should be taken into account when buying a box compression tester?

When buying a box compression tester, look for the capacity of the testing machine, as well as features such as computer controls, overload protection, and the ability to calibrate. Additionally, if you consider high-quality brands, Haida International Equipment stands out as a leading manufacturer that provides packaging testing equipment tailored to your requirements.