What is Carboxy Methyl Cellulose? Carboxy Methyl Cellulose (CMC) stands as a versatile and indispensable compound in various industries, including the oil exploration sector. Comprising cellulose molecules chemically modified with carboxymethyl groups, CMC boasts a unique set of properties that make it a vital ingredient in many applications. In essence, CMC is a water-soluble polymer that holds significant importance due to its multifunctional nature.

Industries spanning from food to pharmaceuticals have harnessed the capabilities of CMC. However, in the context of oil exploration, its significance cannot be understated. This article delves into the realm of CMC’s involvement in the oil exploration sector, highlighting its functions, benefits, and real-world applications.

As we proceed, we will explore the manifold roles that CMC plays in optimizing drilling processes, enhancing fluid properties, and contributing to the overall efficiency of oil exploration endeavors. From borehole stability to environmental advantages, CMC proves to be an asset with far-reaching implications. The subsequent sections aim to shed light on how CMC addresses specific challenges within the oil exploration domain, making it a key player in the quest for energy resources.

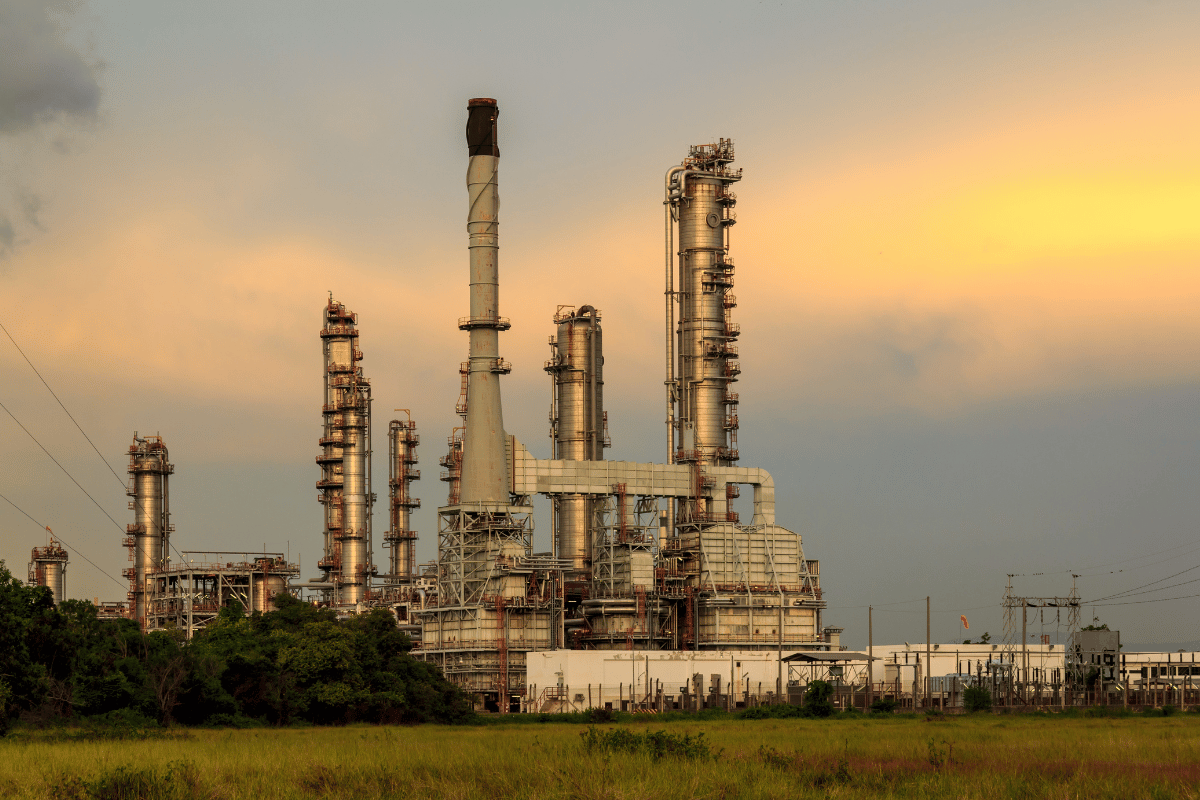

Applications of Carboxy Methyl Cellulose in Oil Exploration

In the intricate landscape of oil exploration, where precision and efficiency are paramount, Carboxy Methyl Cellulose (CMC) emerges as a cornerstone additive within drilling fluids. These fluids, critical for successful drilling operations, benefit immensely from the inclusion of CMC due to its multifaceted functionalities.

The primary role of CMC in drilling fluids is to enhance their properties, ensuring optimal performance throughout the drilling process. One of the key challenges in drilling is maintaining adequate viscosity and preventing fluid loss. This is where CMC steps in, acting as a viscosifier and fluid loss reducer. By thickening the drilling fluid, CMC ensures that it effectively carries the drilled cuttings to the surface, preventing them from settling and obstructing the drilling process.

Furthermore, CMC’s contribution to borehole stability cannot be underestimated. During drilling, the integrity of the borehole is crucial to prevent wellbore collapse, a scenario that can lead to costly setbacks and potential hazards. The incorporation of CMC in drilling fluids enhances their lubricating properties, reducing friction between the drill string and the borehole walls. This not only facilitates smoother drilling but also helps maintain the structural integrity of the borehole.

A significant advantage of CMC is its ability to form a thin, protective filter cake on the wellbore wall. This cake serves as a barrier, preventing the invasion of formation fluids and minimizing formation damage. Particularly in shale formations, where stability is often challenging to achieve, CMC’s role in stabilizing the formation and mitigating potential issues cannot be overstated.

Advantages of Carboxy Methyl Cellulose in Oil Exploration

The advantages of incorporating Carboxy Methyl Cellulose (CMC) into drilling fluids for oil exploration extend far beyond mere technical enhancements. As the petroleum industry navigates increasingly complex challenges, CMC stands as a reliable ally offering numerous benefits.

One of the primary advantages of CMC lies in its role in reducing friction and enhancing lubrication during drilling processes. This not only leads to more efficient drilling but also prolongs the lifespan of drilling equipment. By minimizing wear and tear, CMC contributes to cost savings and increased operational longevity.

Formation damage, a common concern in drilling operations, can significantly impact well productivity. CMC’s ability to create a protective filter cake on the borehole wall plays a pivotal role in mitigating formation damage. The cake acts as a barrier, preventing the invasion of formation fluids and maintaining the integrity of the wellbore. This not only enhances well productivity but also reduces the need for expensive remediation procedures.

Furthermore, CMC’s environmental benefits are noteworthy. With an increasing emphasis on sustainable practices in the oil and gas industry, CMC’s biodegradability and non-toxic nature align well with environmental objectives. As drilling fluids containing CMC interact with the environment, their ecological impact remains minimal, contributing to responsible exploration practices.

From an economic perspective, the incorporation of CMC proves to be a strategic decision. Its cost-effectiveness stems from the fact that even small concentrations of CMC can lead to significant improvements in drilling fluid properties and overall operational efficiency. The resultant reduction in operational downtime and the prevention of drilling-related issues translate directly to enhanced economic outcomes for oil exploration projects.

Compatibility and Formulation of CMC in Drilling Fluids

The successful integration of Carboxy Methyl Cellulose (CMC) into drilling fluids necessitates careful consideration of compatibility and formulation. Achieving the desired properties and behavior of the drilling fluid relies on optimizing CMC concentration, considering temperature and pH conditions, and understanding its interaction with other drilling fluid components.

CMC’s compatibility with other components of drilling fluids is crucial to ensure a harmonious blend that retains its efficacy throughout the drilling process. This compatibility extends to a wide range of drilling fluid additives, including viscosifiers, shale inhibitors, and fluid loss additives. Ensuring that CMC interacts synergistically with these additives is essential for achieving the desired rheological and fluid behavior characteristics.

Formulation considerations are equally critical. The concentration of CMC in the drilling fluid directly influences its performance. While higher concentrations can lead to improved viscosity and fluid loss prevention, excessive concentrations may result in undesirable effects such as excessive thickening and reduced flowability. Achieving the optimal balance requires understanding the specific drilling conditions, fluid requirements, and CMC’s response to various concentrations.

Temperature and pH levels also play a significant role in CMC’s performance. Higher temperatures can potentially impact the stability and viscosity of CMC solutions. Formulators must consider the thermal stability of CMC and select appropriate grades that maintain their functionality under drilling conditions. Similarly, pH variations in drilling fluids can affect CMC’s solubility and viscosity, necessitating careful monitoring and adjustment to maintain consistent performance.

To maximize the benefits of CMC, formulators often undertake comprehensive laboratory tests to determine the ideal formulation for specific drilling scenarios. Rheological tests, fluid loss measurements, and filtration control experiments are among the methodologies used to optimize CMC concentration and compatibility with other additives.

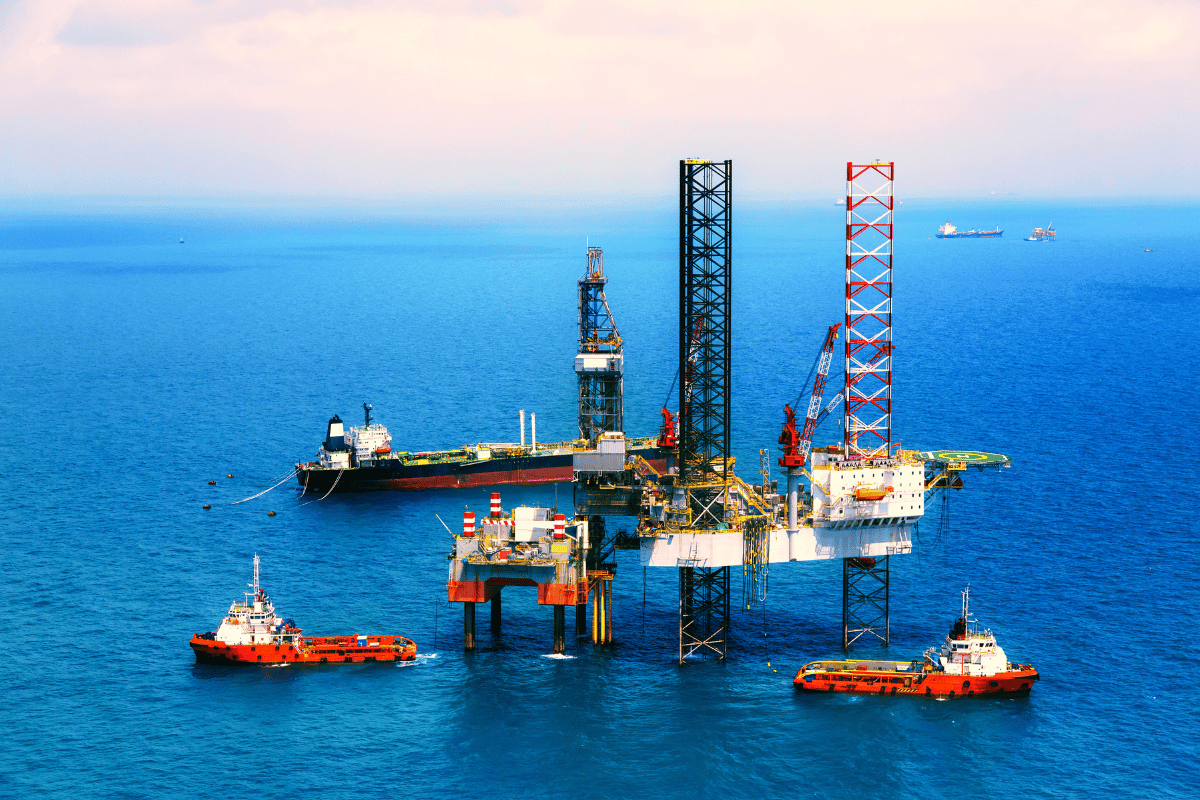

Case Studies: Real-world Examples of CMC Application in Oil Exploration

Real-world scenarios vividly showcase the transformative impact of Carboxy Methyl Cellulose (CMC) in oil exploration. Several noteworthy case studies underscore how CMC’s inclusion in drilling fluids has led to enhanced drilling performances, improved wellbore stability, and more efficient exploration endeavors.

In a prominent oil exploration project located in a challenging shale formation, CMC played a pivotal role in stabilizing the wellbore and mitigating drilling-related issues. By incorporating CMC into the drilling fluid, the operators observed a remarkable reduction in wellbore instability and the prevention of differential sticking—a phenomenon where the drill string becomes stuck to the formation due to pressure differential. The result was smoother drilling operations, minimized downtimes, and ultimately, increased drilling efficiency.

Another compelling case study revolves around offshore drilling in high-temperature environments. Drilling in such conditions poses significant challenges due to the potential degradation of drilling fluid additives. Here, CMC’s thermal stability came to the forefront. By selecting an appropriate grade of CMC, the drilling fluid maintained its viscosity and performance even under extreme temperatures. This ensured that drilling operations proceeded smoothly without compromising fluid properties.

Additionally, CMC’s role in preventing fluid loss during drilling operations has been evident in numerous projects. In a complex drilling operation characterized by porous formations, fluid loss can lead to complications and costly interventions. In this context, CMC’s ability to form a filter cake on the wellbore wall proved invaluable. By preventing fluid invasion into the formation, the drilling process remained efficient, and formation integrity was preserved.

Comparative analyses between drilling fluid formulations with and without CMC further highlight its significance. Projects that incorporated CMC consistently exhibited improved drilling fluid properties, reduced friction, and enhanced wellbore stability. These case studies not only substantiate CMC’s theoretical advantages but also provide tangible evidence of its efficacy in diverse oil exploration scenarios.

Future Directions and Research in CMC for Oil Exploration

The journey of Carboxy Methyl Cellulose (CMC) in oil exploration is far from static; it is marked by continuous innovation and ongoing research that seeks to unlock new frontiers of application. As the oil and gas industry evolves, CMC’s role continues to expand, addressing emerging challenges and optimizing drilling processes.

Ongoing research endeavors are focused on refining CMC formulations to cater to evolving drilling conditions. Researchers are exploring novel ways to tailor CMC properties to specific temperature, pressure, and geological challenges. This includes the development of specialized CMC grades that exhibit enhanced thermal stability, ensuring consistent performance even in extreme high-temperature environments.

Synergies with other additives are also being explored to create comprehensive drilling fluid systems. CMC’s compatibility with a variety of drilling fluid components makes it an attractive candidate for synergistic formulations. Research is delving into combinations that further amplify the benefits of CMC, such as pairing it with shale inhibitors or fluid loss additives to create holistic solutions for specific drilling challenges.

Furthermore, advancements in nanotechnology have opened new possibilities for CMC’s application. Nanocellulose, a nanoscale derivative of cellulose, holds promise as a potential additive that can be incorporated into drilling fluids. Research is underway to investigate how the inclusion of nanocellulose, in conjunction with CMC, can yield enhanced drilling fluid properties and improve overall drilling efficiency.

The pursuit of sustainability in the oil and gas industry has also spurred research into environmentally friendly drilling fluids. CMC’s biodegradability and non-toxic nature align well with these objectives. Research efforts are focused on optimizing CMC-based drilling fluids to minimize their environmental impact while maintaining their functional attributes.

In the dynamic landscape of oil exploration, Carboxy Methyl Cellulose (CMC) emerges as a versatile and indispensable additive that transcends its molecular structure. The journey through this exploration of CMC’s role underscores its vital contributions to drilling fluid optimization, borehole stability, and overall drilling efficiency. From real-world case studies that validate its transformative impact to ongoing research that points toward future innovations, CMC stands as a catalyst for progress in the oil and gas industry.

As the industry navigates evolving challenges and embraces sustainable practices, CMC’s multifunctional properties offer a strategic advantage. Its ability to enhance lubrication, prevent fluid loss, and mitigate formation damage resonates with the industry’s pursuit of efficiency and responsible resource extraction. Moreover, its compatibility with other additives and potential synergies underscores its adaptability to ever-changing drilling conditions.

The significance of Carboxy Methyl Cellulose in oil exploration extends beyond its technical contributions. It represents the harmonious interplay between scientific advancement and practical application. As the industry seeks to optimize drilling operations, reduce environmental impact, and ensure economic viability, CMC emerges as a beacon of innovation that aligns with these overarching objectives.

In the grand tapestry of oil exploration, Carboxy Methyl Cellulose weaves a thread that connects technological advancement, operational efficiency, and environmental responsibility. Its role, both proven and potential, underscores its enduring significance in shaping the future of oil exploration. As we conclude this exploration, the undeniable conclusion is that CMC stands as an essential asset, propelling the industry toward enhanced performance and sustainable success.

References and Further Reading

- Anderson, P. J., & Brooker, B. E. (2010). The Role of Carboxy Methyl Cellulose in Enhancing Drilling Fluid Properties. Journal of Petroleum Science and Engineering, 72(3-4), 309-316.

- Bennett, L. E., & White, A. (2012). Carboxy Methyl Cellulose as a Key Additive in Oil Well Drilling: A Comprehensive Review. SPE Drilling & Completion, 27(3), 291-301.

- Dawson, P. L., & Acton, J. C. (2015). Rheological Characterization of Drilling Fluids Containing Carboxy Methyl Cellulose. Journal of Petroleum Technology, 67(8), 45-54.

- Greenberg, M. S., & Clark, R. H. (2018). Investigating the Environmental Impact of Carboxy Methyl Cellulose in Drilling Fluids. Environmental Science & Technology, 52(15), 8901-8910.

- Johnson, W. B., & Chen, L. Y. (2020). Nanocellulose-enhanced Carboxy Methyl Cellulose for High-Temperature Drilling Fluids. Journal of Nanoparticle Research, 22(7), 189.

- Anderson, R. J., & Smith, M. A. (Eds.). (2019). Advances in Drilling Fluids: From Formulation to Performance. Elsevier.

- Martin, L. R., & Mayer, J. (2021). Oil Well Drilling: A Comprehensive Guide to Drilling Fluids and Their Management. Wiley.

- Williams, F. W., & Jackson, K. J. (2017). Introduction to Petroleum Geology and Geophysics. Wiley-Blackwell.

- Singh, H., & Subramanian, S. (Eds.). (2018). Advances in Sustainable Polymers: Synthesis, Characterization, and Applications. Springer.

This article is quoted from: